COSMO SOURCING BLOG

How to Find Flat Pack Furniture Manufacturers in Vietnam: The Complete Guide

The global furniture industry has undergone a remarkable transformation in recent decades, with flat-pack furniture leading the charge. Ready-to-assemble (RTA) and knockdown furniture have revolutionized how consumers purchase, transport, and assemble furniture in their homes. As demand for affordable, space-efficient furniture continues to grow, businesses worldwide are seeking reliable manufacturing partners who can deliver quality products at competitive prices.

Vietnam has emerged as one of the world's premier destinations for sourcing flat-pack furniture, offering an ideal combination of skilled craftsmanship, competitive costs, and modern manufacturing capabilities. This comprehensive guide will walk you through everything you need to know about finding and partnering with flat-pack furniture manufacturers in Vietnam.

What is the Lacey Act? // What Wood Importers Need to Know

The global sourcing landscape has become increasingly complex, with importers facing a web of regulations that can significantly impact their business operations. Among these regulations, the Lacey Act stands out as one of the most critical yet misunderstood pieces of legislation affecting international trade. Originally designed to combat wildlife trafficking, this century-old law has evolved into a comprehensive framework that impacts virtually every importer dealing with plant-based products.

For businesses sourcing wood, furniture, paper goods, textiles, and countless other plant-derived materials, understanding the Lacey Act isn't just about legal compliance—it's about protecting your business from devastating consequences. Non-compliance can result in substantial fines, product seizures, criminal charges, and irreparable damage to your company's reputation. In today's interconnected global economy, where supply chains span continents and consumer awareness of sustainability is at an all-time high, the Lacey Act has never been more relevant.

How to Build Resilient Supply Chains Through Strategic Sourcing Diversity

The past few years have significantly altered how businesses approach supply chain management. From the COVID-19 pandemic's widespread manufacturing shutdowns to the Ever Given container ship blocking the Suez Canal, from semiconductor shortages that paralyzed automotive production to geopolitical tensions disrupting critical trade routes, organizations worldwide have learned that traditional supply chain models built on efficiency alone are dangerously fragile.

In this new reality, resilience has become the watchword for supply chain leaders. But what does "resilient" actually mean in practical terms? A resilient supply chain can maintain operations during disruptions, adapt quickly to changing conditions, and recover swiftly from setbacks. The key to achieving this resilience lies not in building bigger buffers or more redundant systems, but in embracing strategic diversity across suppliers, geographies, and capabilities.

Diversity in supply chains means deliberately cultivating multiple sources, pathways, and partnerships that reduce dependence on any single point of failure. It's about creating an ecosystem of suppliers that brings different strengths, locations, and capabilities to the table, ensuring that when one avenue closes, several others remain open.

What is Tariff Engineering? How to Stay Compliant when Redesigning Products for Tariffs

Two critical strategies that often emerge in discussions about cost optimization and regulatory compliance are tariff engineering and trade compliance. While both approaches aim to help companies succeed in the global marketplace, they represent fundamentally different philosophies and methodologies that can significantly impact a business's bottom line and legal standing.

Understanding the distinction between these approaches isn't just an academic exercise—it's essential for any business engaged in international trade. The difference between legitimate cost-saving strategies and potentially costly compliance violations can mean the difference between sustainable growth and devastating penalties. Companies that master this balance often find themselves with significant competitive advantages, while those that fail to do so may face serious legal and financial consequences.

Cosmo Sourcing, a traditional product sourcing company based in Vietnam, has emerged as a crucial ally for businesses seeking to navigate these complex waters. By connecting companies with thoroughly vetted manufacturers and providing comprehensive sourcing services, Cosmo Sourcing helps ensure that sourcing strategies align with both cost-saving objectives and stringent compliance requirements.

Low-Cost Country Sourcing in 2025 Guide

Companies like Cosmo Sourcing are at the forefront of this evolution, helping businesses to navigate the new realities of global procurement effectively. They report that approximately 56% of organizations are investing more into sourcing partnerships that emphasize ethical labor practices and sustainable operations. The traditional playbook of simply identifying the cheapest manufacturing sites is no longer adequate in today's interconnected economy, forcing companies to develop new methodologies that evolve with changing market conditions.

As companies engage with these new sourcing paradigms, they are discovering that innovation and adaptability are crucial. A staggering 80% of sourcing professionals have indicated that the ability to pivot quickly in response to global events has become a key competitive advantage. Thus, the role of strategic sourcing is not just about cost but involves a holistic assessment of global market trends, regulatory compliance, and the need for sustainable pursuits, enabling organizations to thrive in a complex and ever-changing landscape.

How to Negotiate with Vietnamese Suppliers // Business Etiquette in Vietnam

Vietnam has emerged as one of Asia's most dynamic sourcing destinations, attracting businesses worldwide with its competitive pricing, skilled workforce, and strategic location. However, successful sourcing in Vietnam requires more than just finding the right supplier—it demands a deep understanding of the cultural nuances that shape business relationships and negotiations.

At Cosmo Sourcing, we've been navigating the Vietnamese business landscape since 2014, building lasting partnerships between international buyers and local suppliers. Our decade of experience has taught us that cultural intelligence isn't just helpful—it's essential for securing favorable terms, maintaining quality standards, and building sustainable supply chains. Through our established presence in Vietnam and extensive network of over 14,000 factory contacts, we've developed proven strategies for bridging cultural gaps and facilitating successful supplier relationships.

The Hidden Costs of Poor Supplier Communication // How Miscommunication Hurts Your Bottom Line

In global sourcing, a single misunderstood email can result in millions of dollars in losses. A vague specification can result in a warehouse full of unusable products. An unclear timeline transforms into empty shelves during peak season. While businesses obsess over unit costs and shipping rates, they often overlook the most expensive variable in their supply chain: communication.

Poor supplier communication isn't just an operational inconvenience—it's a strategic vulnerability that compounds costs across every aspect of your business. From direct financial losses to missed innovation opportunities, the true price of communication breakdowns extends far beyond what appears on any invoice.

How to Find Patio Furniture Manufacturers in Vietnam //List Of Top Patio Furniture Manufacturers In Vietnam

Vietnam has emerged as a powerhouse in the global furniture manufacturing industry, particularly excelling in the production of outdoor and patio furniture. With its strategic location, competitive pricing, and skilled workforce, the country has become a go-to destination for businesses seeking high-quality furniture at reasonable costs. This comprehensive guide will walk you through everything you need to know about finding and working with patio furniture manufacturers in Vietnam.

The Vietnamese furniture industry has experienced remarkable growth over the past decade, transforming from a predominantly domestic-focused sector to a major global exporter. The country's furniture exports have grown from $5 billion to nearly $20 billion over the past decade, with outdoor furniture representing a significant portion of this trade. Vietnam's manufacturers have mastered working with a wide range of materials, from traditional hardwoods such as acacia and eucalyptus to modern synthetic materials like PE wicker and powder-coated aluminum, making it an ideal sourcing destination for diverse patio furniture needs.

How to Find Hospitality Furniture Suppliers // Best Countries to source FFE Furniture in 2025

When guests step into a hotel lobby, sink into a plush restaurant banquette, or relax by the poolside at a resort, the quality and design of the furniture are among the first things they notice—even if subconsciously. Hospitality furniture is not just about aesthetics; it’s about comfort, durability, and the ability to create memorable experiences for visitors.

Yet, behind every beautifully appointed property is a crucial decision: selecting the right furniture suppliers. The hospitality industry faces unique demands—furniture must withstand heavy use, align with the brand’s identity, meet strict safety and environmental standards, and be delivered on time and budget. With the global landscape for sourcing changing rapidly, finding reliable, high-quality suppliers is more strategic than ever.

At Cosmo Sourcing, we have helped countless hotels, resorts, restaurants, and hospitality brands elevate their spaces by connecting them directly with trusted manufacturers in Vietnam, Mexico, Southeast Asia, and beyond. In this comprehensive guide, we’ll walk you through everything you need to know about hospitality furniture suppliers in 2025—from supplier categories and procurement steps to the latest trends, top sourcing destinations, and actionable advice for making your next project a success.

DDP Incoterm: The Right and Wrong Way // What Every Importer Needs to Know (And Why DDP Fraud Is On the Rise)

In the world of international trade, Incoterms (International Commercial Terms) serve as the universal language that defines who is responsible for what during a shipment. Among these terms, DDP (Delivered Duty Paid) has become increasingly attractive to importers, especially those new to international sourcing. The appeal is obvious: one price, one responsibility, and the promise that your supplier will handle everything from factory to your doorstep.

However, this apparent simplicity comes with hidden dangers that many importers discover too late. The rise of fraudulent DDP schemes, particularly from Chinese suppliers, has created a minefield of legal and financial risks that can devastate unprepared businesses. What seems like a convenient "all-inclusive" shipping option often becomes a costly lesson in international trade compliance.

The reality is that DDP transactions, when done incorrectly, can expose importers to customs penalties, retroactive duties, and even the loss of import privileges. Understanding the difference between legitimate DDP arrangements and fraudulent schemes has never been more critical for importers looking to protect their businesses.

The Top 12 Countries for Bags, Backpacks, and Luggage: A Global Manufacturing Guide

The global bags and luggage market has reached over $60 billion and is projected to hit $85 billion by 2030. China continues to dominate this landscape, producing 70% of the world's bags and luggage. However, smart brands are now adopting "China Plus One" strategies, maintaining Chinese suppliers while developing alternative manufacturing sources to enhance supply chain resilience, optimize costs, and leverage specialized capabilities.

This diversification trend has created opportunities in countries offering unique advantages in craftsmanship, cost-effectiveness, geographic proximity, and niche specializations. Rather than replacing China entirely, successful brands build multi-country sourcing strategies that leverage each region's strengths.

Key factors to consider when sourcing internationally include quality and craftsmanship, total cost of ownership, supplier reliability, lead times, scalability, access to raw materials, and compliance with social and environmental standards. The most successful sourcing strategies strike a balance among these factors across multiple manufacturing regions.

How to Find Pet Products Manufacturers in Vietnam // Top Pet Toys Factories In Vietnam List

Vietnam has emerged as a leading sourcing destination for pet products, offering a compelling alternative to traditional manufacturing hubs. The country combines competitive costs with a skilled workforce, strong textile and furniture sectors, and remarkable supply chain resilience tested and proven through global disruptions. Vietnamese manufacturers have demonstrated their ability to adapt quickly to changing market conditions while maintaining consistent quality and delivery standards.

Companies like Cosmo Sourcing have established strong track records in matching international clients with reliable Vietnamese manufacturers, facilitating successful partnerships that drive business growth. With years of experience navigating the Vietnamese market, sourcing experts understand the nuances of local business practices and can identify manufacturers who align with specific brand requirements and values.

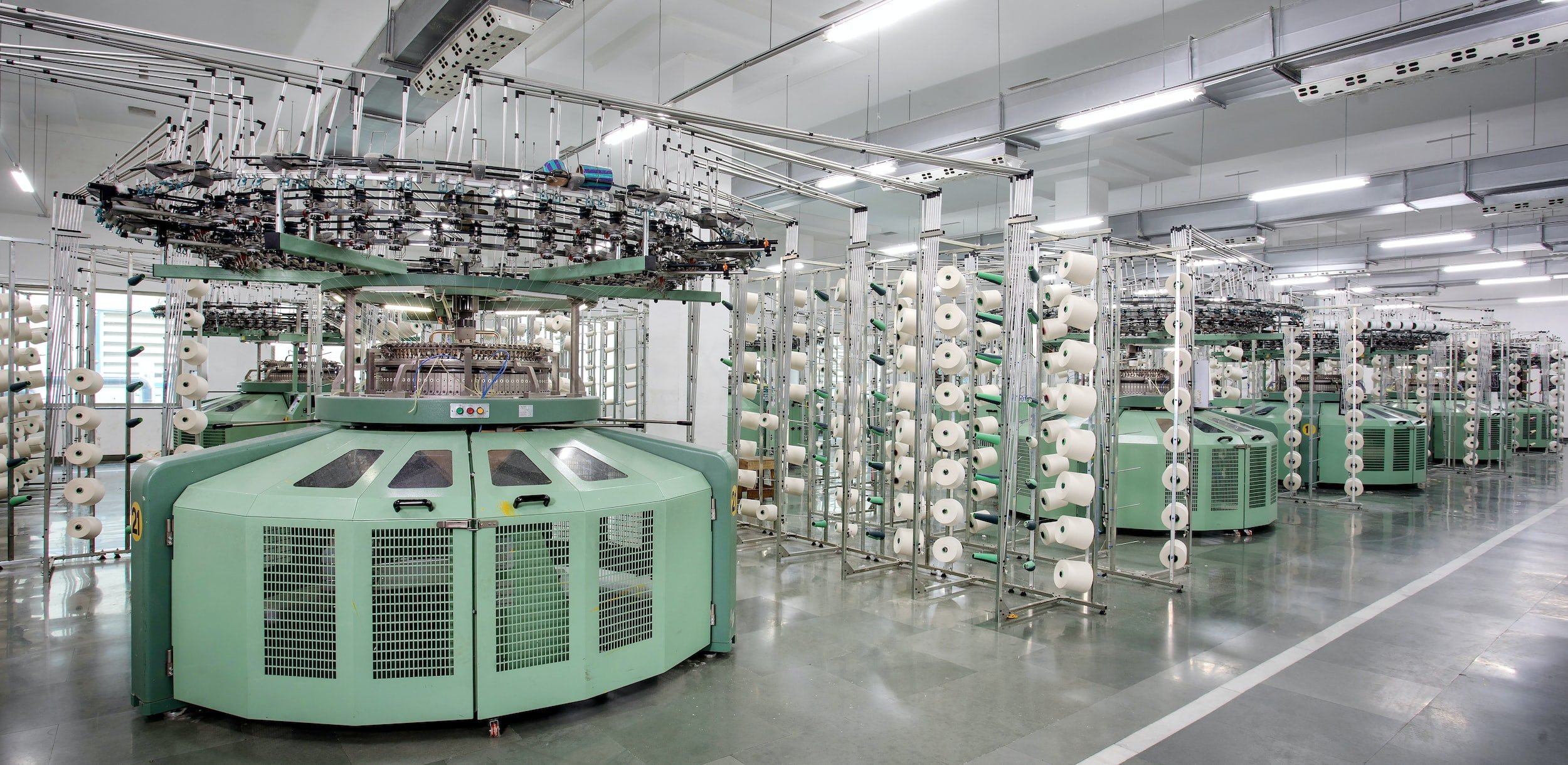

The Best Countries to Source Apparel and Clothing (Outside of China) // Ultimate Guide for 2025

The global apparel sourcing landscape has undergone a dramatic transformation in recent years. While China has long dominated as the world's manufacturing powerhouse, producing over 40% of global garments, smart brands are increasingly diversifying their supply chains. Rising labor costs, trade tensions, tariff uncertainties, and the harsh lessons learned from COVID-19 supply chain disruptions have made "China+1" strategies not just advisable but essential for long-term business resilience.

Today's savvy apparel brands understand that putting all their manufacturing eggs in one basket, regardless of how efficient that basket might be, creates unacceptable risk. Beyond risk mitigation, companies are discovering that alternative sourcing destinations often offer compelling advantages: lower costs, specialized expertise, faster lead times to certain markets, and improved sustainability credentials that resonate with increasingly conscious consumers.

What is Product Sourcing? // The Ultimate Guide to Product Sourcing

In today's competitive marketplace, successful enterprises recognize the critical importance of effective product sourcing—the strategic process of identifying and establishing relationships with reliable suppliers. Whether launching a startup or expanding an established company's product range, mastering efficient sourcing strategies is fundamental to maintaining market relevance and profitability.

This comprehensive guide explores the essentials of product sourcing and provides actionable steps for beginning your procurement journey confidently.

Mexico vs. Vietnam Product Sourcing 2025 // Best Product Sourcing Destinations in 2025

Recent trade disputes, pandemic-related disruptions, and growing national security concerns have accelerated this transition, prompting companies to seek more resilient and geographically distributed supply networks. Mexico and Vietnam offer distinct advantages, making them attractive destinations for companies looking to reduce their dependence on Chinese manufacturing.

This article comprehensively compares Mexico and Vietnam as sourcing destinations, examining their relative strengths and weaknesses across cost structures, manufacturing capabilities, trade policies, and supply chain dynamics. By understanding these factors, businesses can make more informed decisions about effectively diversifying their supply chains in an increasingly complex global environment.

How to Vet, Audit, and Verify Suppliers Globally // Ultimate Step-by-Step Guide

ntrepreneurs rush this critical decision, lured by attractive pricing or ambitious promises that mask underlying risks.

The consequences of inadequate supplier vetting range from merely expensive to catastrophic. We've witnessed promising startups collapse after discovering their "manufacturer" was a trading company with no production capabilities, leaving them with depleted capital and nothing to show. Established businesses have watched their reputations crumble when substandard materials from unvetted suppliers led to product failures or safety issues. These mistakes' financial, legal, and brand damage often prove insurmountable.

At Cosmo Sourcing, we've vetted over 14,000 factories across Asia during our decade in business. This comprehensive experience has taught us that thorough supplier vetting isn't just a due diligence checkbox—it's arguably the most consequential decision in your entire product development journey. The systematic approach we've developed has helped over 5,000 clients navigate this complex landscape successfully, and we've distilled these lessons into this practical guide.

Nearshoring vs Low-Cost Country Sourcing: Pros and Cons

In today's highly competitive global marketplace, businesses constantly seek strategies to optimize their supply chains while maintaining quality and meeting customer demands. Two approaches have emerged as dominant strategies in the sourcing landscape: Low-Cost Country Sourcing (LCCS) and Nearshoring. As companies navigate post-pandemic recovery and increasing geopolitical uncertainties, choosing the right sourcing strategy has never been more critical.

This comprehensive guide explores both strategies, comparing their advantages, challenges, and ideal use cases to help your business make informed decisions that align with your needs and goals.

How to Find Good Sourcing Companies and Avoid the Bad Ones

The consequences of choosing the wrong manufacturing partner can be severe: production delays that derail your launch timeline, quality issues that damage your brand reputation, unexpected costs that eat into your profit margins, and communication breakdowns that leave you frustrated and uncertain. Conversely, partnering with the right sourcing agent can transform your supply chain experience, streamlining the entire process and allowing you to focus on what matters most, scaling your business and delighting your customers.

At Cosmo Sourcing, we've guided hundreds of entrepreneurs and businesses through the complex landscape of global manufacturing. Our team brings years of expertise to the table, and we are committed to the principles of transparency, quality, and client success that have made us a trusted partner in product sourcing worldwide.

How To Find Golf Clothing Factories In Vietnam // Top Golf Clothing Manufacturers In Vietnam List

Vietnam offers compelling advantages for golf apparel sourcing, including a strong textile manufacturing foundation, skilled labor with technical expertise in performance fabrics, competitive pricing, and favorable trade agreements. The country has reduced its reliance on agriculture, with manufacturing becoming a key pillar of its modern economy. One of Vietnam's main competitive advantages lies in its skilled workforce and relatively low labor costs.

This comprehensive guide will help you find, vet, and partner with reliable golf apparel manufacturers in Vietnam. This will ensure your brand can capitalize on the country's manufacturing capabilities while maintaining the quality and performance standards golf enthusiasts expect.

How To Find Linen Manufacturers in Vietnam // What Type of Linen Goods And Clothing Is Made In Vietnam

n recent years, Vietnam has become one of the world's most promising textile manufacturing hubs, with linen production emerging as a bright spot. The country has steadily built its reputation in the global textile landscape, evolving from basic garment assembly to sophisticated fabric production that includes high-quality linen.

As someone who's spent considerable time navigating Southeast Asian supply chains, I've witnessed Vietnam's textile industry flourish firsthand. Vietnamese manufacturers have rapidly adopted modern equipment and techniques while maintaining competitive pricing, creating an increasingly compelling alternative to Chinese mass production and European premium manufacturing.

This manufacturing evolution creates exciting opportunities for businesses of all sizes. Whether you're a fashion brand looking to create a sustainable linen collection, a homewares company seeking quality table linens, or an entrepreneur with a vision for innovative linen products, Vietnam offers manufacturing partners capable of handling everything from small-batch premium collections to large-scale production runs.