How to Create a Product Specification Sheet for Manufacturing // Step-By-Step Guide

How to create a product spec sheet that ensures you get the exact product you want from your supplier!

A product specification sheet is the single most important document in your sourcing process. It tells a manufacturer exactly what to build, what materials to use, how it should look, and what standards it needs to meet. Get it right, and you receive accurate quotes and samples that match your expectations. Get it wrong, and you spend months going back and forth on revisions, or worse, you end up with a finished product that does not match what you had in mind.

We have helped thousands of clients get products manufactured across Vietnam, China, and other markets since 2012. The spec sheet is where most sourcing projects either gain momentum or start falling apart. This guide walks you through what to include, how to write it so factories actually follow it, and the mistakes we see buyers make over and over again.

What Is a Product Specification Sheet?

A product specification sheet is a document that outlines every detail a manufacturer needs to quote, sample, and produce your product. It covers dimensions, materials, colors, packaging, compliance requirements, and reference images, all organized in a format that a factory team can read and act on.

Think of it as the contract between your vision and the factory floor. Your manufacturer will use this document at every stage: generating a price quote, ordering raw materials, building your sample, running production, and passing quality inspections. If a detail is not in the spec sheet, the factory will either guess or default to whatever is cheapest. Neither outcome is good for you.

A strong spec sheet is also your best tool for comparing quotes. When you send the same detailed document to multiple factories, you can compare pricing on equal terms. Without one, you are comparing quotes based on different assumptions, and the cheapest quote might be cheap because the factory assumed lower-grade materials.

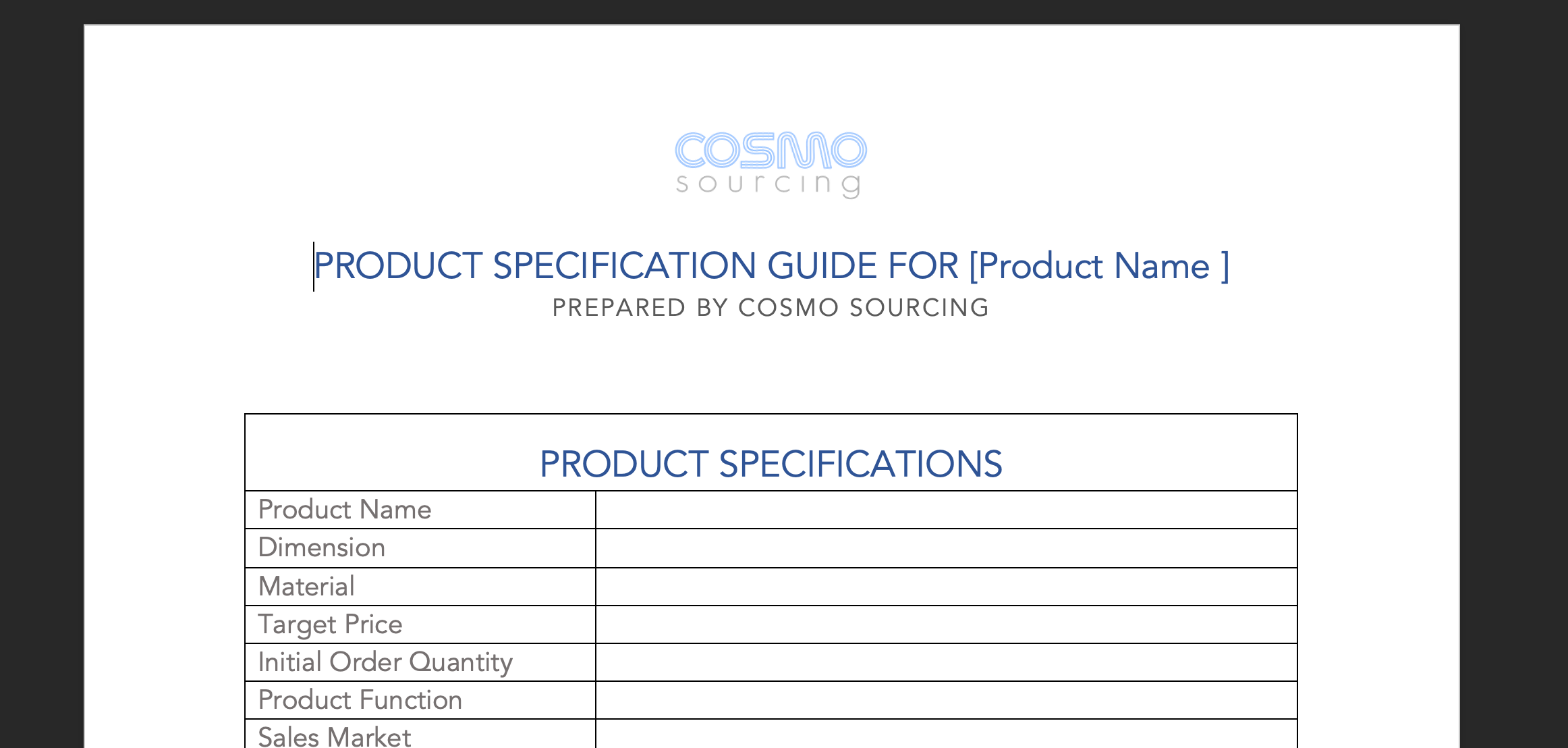

Here’s a free Product Specification template!

If you’re unsure what a product sheet should look like, please download our template. Our product spec sheet is a basic template, so you should make significant changes to suit your product. Regardless, fill in the email, and we’ll send you the template we use for our projects!

Enter your email below!

What to Include in Your Product Specification Sheet

Every product is different, but most spec sheets follow a similar structure. Here are the core sections you need.

Product Summary

Keep this to a few sentences. Describe what the product is, how the end customer uses it, and any context the factory needs to understand the intent. Do not write a marketing pitch. The goal is to give the production team a quick mental picture before they dive into the technical details.

Product Specifications

This is your raw data section: overall dimensions, weight, colors (use Pantone codes when exact color matters), materials, target price, estimated order quantity, and intended market. Organize it as a table or bulleted list for easy scanning. If there are tolerances (acceptable variation in size or weight), state them here. Factories expect this level of precision, and leaving it out invites interpretation.

Bill of Materials

List every material the factory will use, and be specific about each. "Strong fabric" tells the factory nothing. "60D ripstop nylon, 210T, PU-coated" tells them exactly what to source. Run through every component of your product: shell material, lining, hardware, thread, zippers, adhesives, labels, and anything else that goes into the finished piece. Most factories specializing in your product category will have common materials in-house, but anything unusual may need to be sourced separately, which affects lead time and cost.

Reference Photos and Diagrams

Photos are the most-read section of any spec sheet, especially when you are working with factories where English is a second language. Visual references cross language barriers in a way that text cannot.

Include two types of images. First, product photos: if a physical product or prototype exists, photograph it from multiple angles with a measuring tape or ruler visible for scale. If the product does not exist yet, use sketches, CAD renderings, or annotated mockups. Second, technical diagrams: show dimensions, cross-sections, and detail views of specific features, such as stitching patterns, closures, or joint types. Use a basic image editor to add arrows and labels pointing to specific details. The more visual clarity you provide, the fewer assumptions the factory needs to make.

Packaging

Packaging is easy to overlook, but it protects your product during shipping and shapes the customer experience. Specify the inner packaging (poly bags, tissue paper, retail box) and the master carton dimensions. The master carton is the large box that holds multiple units for bulk shipping. A typical master carton holds 50 to 200 units, depending on product size. Include packing configuration (how units are arranged inside), any inserts or padding, and labeling requirements for the outer carton, such as barcodes, shipping marks, and handling instructions.

Product Compliance Standards

Many products must meet specific safety and regulatory standards before they can be imported and sold. These vary by country and product category. Common examples include CPSC requirements for consumer products entering the United States, CE marking for the European market, and various ASTM or ISO testing standards depending on your product type. Regulatory approvals are typically the buyer's responsibility, while factory certifications, such as ISO 9001, are the supplier's responsibility. If you are unsure which standards apply to your product, a product sourcing company or a compliance consultant can help you identify them. Rates and requirements vary by country, so check the latest regulations for your specific importing market.

How to Write a Spec Sheet Factories Will Actually Follow

Knowing what sections to include is only half the job. How you write the spec sheet determines whether factories follow it or ignore the details.

Research How Your Product Is Manufactured

Before you write a single line, understand how your product gets made. Watch manufacturing process videos, read industry publications, and study the production steps involved. This grounds your spec sheet in reality. We have seen clients request features that sound great on paper but are impractical to manufacture, or that require combining processes from two different factory types. Understanding the basics of production helps you write specifications that a factory can actually execute.

Study Similar Products

Look at comparable products on Amazon, Alibaba, and competitor websites. Read their product descriptions for materials, dimensions, and features. This is not about copying. It is about benchmarking what is standard in your category, so you know where your product aligns and where it differs. Pay attention to the certifications listed in product descriptions as well. These often signal which compliance standards are expected for your product type. Our guide on tariffs, customs duties, and import regulations covers more on what to look for.

Write for Someone Who Has Never Seen Your Product

Assume the factory knows nothing about your product or your market. Use simple, direct English. Avoid idioms, abbreviations, and jargon that might not translate well. Remember that your spec sheet will likely be read by salespeople, engineers, and production workers, some of whom will use translation software. Keep sentences short. Define any technical terms the first time you use them. If a detail matters, state it explicitly rather than assuming it is obvious.

Design for Manufacturability

Review your specifications with manufacturing constraints in mind. The more steps a product requires, the more expensive it becomes. If cost matters (and it usually does), simplify where you can without compromising the product. Ideally, your product should be producible in a single factory, with no outsourced components. Every time a factory needs to coordinate with an outside supplier, you add lead time, cost, and potential quality issues.

Expect to Revise

Your spec sheet is a living document. It is completely normal to go through multiple revisions between the first draft and final production. Each round of samples may reveal details that need adjustment. At Cosmo Sourcing, we regularly revise spec sheets with clients three or four times before a product reaches mass production. The important thing is to start with a thorough first version and refine from there, rather than sending a vague document and hoping the factory fills in the gaps.

Common Spec Sheet Mistakes That Cost You Money

After more than a decade of product sourcing across Asia, we see the same spec sheet mistakes come up repeatedly. Each one leads to either incorrect samples, inaccurate quotes, or production issues that could have been prevented.

Vague Material Descriptions

"High-quality leather" means something different to every factory. Without specifying the type of leather, thickness, finish, and grade, you will get whatever the factory defaults to, which is usually whatever is cheapest and available. The same applies to plastics, metals, fabrics, and every other material category. Be specific.

Missing Tolerances and Defect Criteria

If you do not define acceptable variation, the factory defines it for you. State tolerances for dimensions and weight, and define what counts as a defect. For example: "Any scratch longer than 3mm on a visible surface is a major defect." This gives both your factory and any third-party inspector a clear standard to work against during quality checks.

Poor or Missing Photos

A spec sheet with no photos, or only low-resolution images, forces the factory to interpret your text descriptions. Even well-written text leaves room for misunderstanding. We have seen products come back with the right specifications on paper but completely wrong in execution because the factory interpreted a vague description differently than the buyer intended. Annotated, high-resolution photos prevent this.

Ignoring Packaging Specifications

If you skip the packaging section, the factory will use generic packaging, which may not protect your product during international shipping and will not help your brand at the point of sale. We have seen clients receive their first shipment with damaged products because the inner packaging was not specified and the factory used thin poly bags with no padding.

Not Including Compliance Requirements

Skipping compliance standards does not make them optional. It just means you discover the gap later, often after production is complete and you are trying to clear customs. Identify the standards your product needs to meet before you send the spec sheet, and include them as a requirement. This also helps factories self-select: if a factory cannot meet your compliance standards, it is better to know that at the quoting stage than after you have paid for production.

Custom Products: Tooling, Molds, and Design Files

If your product involves custom shapes, components, or proprietary designs, expect additional upfront costs before production begins.

Tooling

Tooling refers to the machinery, jigs, fixtures, and equipment a factory needs to produce your specific product. When vetting factories, confirm they have the necessary equipment. The best way to verify this is a factory visit or a third-party factory audit. Do not take a supplier's word for it without verification.

Molds

Injection molds are one of the most common tooling costs we encounter. A mold is a metal cast that gets injected with material (usually plastic) to form a part. Quality molds can cost several thousand dollars depending on complexity, but they are a one-time investment and can last for years of production runs. Always clarify who owns the mold: you should retain ownership so you can move production to a different factory if needed.

CNC and 3D Printing

Both processes require digital design files (typically CAD files) created by a trained designer. CNC machines carve objects from existing material, while 3D printers build them layer by layer. If your product requires either process, factor in the cost of professional design file creation. These files become part of your spec sheet package and should be included when you send requirements to factories.

How Your Spec Sheet Gets Used After You Send It

Understanding the lifecycle of your spec sheet helps explain why thoroughness matters at every stage.

First, factories use it to generate quotes. The more detailed your spec sheet, the more accurate the quote. Vague spec sheets produce vague quotes, and vague quotes always lead to price surprises later. If you are sending your spec sheet to multiple factories to compare pricing, a detailed document ensures you are comparing apples to apples. Understanding product sourcing fundamentals and how incoterms affect your landed cost helps you evaluate those quotes more effectively.

Second, the factory uses it to build your sample. At Cosmo Sourcing, we turn the spec sheet into a sample evaluation checklist. When the sample arrives, we review it line by line against the original specifications, checking every dimension, material, color, and feature. Anything that does not match gets flagged for revision before production starts.

Third, during mass production, the spec sheet serves as the factory floor reference. Production workers and quality control staff refer back to it throughout the run. It also becomes the basis for any third-party pre-shipment inspections.

Format and Delivery Tips

Most spec sheets start as Word or Excel documents, which makes them easy to edit during the drafting and revision process. When you are ready to send the final version to a factory, convert it to PDF. This prevents accidental formatting changes and ensures the factory sees exactly what you intended.

Include your company name, contact information, and a page number on every page. Spec sheets get emailed, printed, and passed between departments at the factory. If a page gets separated, anyone who picks it up should be able to identify what it belongs to and who to contact with questions.

Use version numbering (v1, v2, v3) and dates so that everyone is always working from the latest revision. Once production starts, the final spec sheet version becomes the binding reference document for quality control.

Take Control of Your Sourcing with the Sourcing Kit

Creating a solid product spec sheet is the foundation of any successful sourcing project, but it is just one piece of the puzzle. The Cosmo Sourcing Kit gives you the tools and guidance to manage the entire process from planning through production and shipping.

The Kit includes product spec sheet templates, request-for-quote templates, supplier communication scripts, sample evaluation checklists, contract templates (including NNN agreements in multiple languages), quality control checklists, and step-by-step guides covering everything from finding and vetting suppliers to negotiating terms, managing production, and coordinating logistics. It is built from over a decade of hands-on sourcing experience across Vietnam, China, and other manufacturing markets.

Whether you are sourcing your first product or streamlining an existing supply chain, the Sourcing Kit gives you the structure and resources to do it with confidence.

Learn more and sign up at cosmosourcing.com/sourcing-kit